How Mate Rimac is supercharging electric cars

Simply sign up to the Electric vehicles myFT Digest -- delivered directly to your inbox.

Not for nothing is Mate Rimac sometimes called “Europe’s Elon Musk”. Both run groundbreaking electric carmakers that have claimed speed records and won plaudits. Both have unconventional manufacturing locations — Tesla in California, Rimac Automobili on the outskirts of Zagreb in Croatia.

When Tesla launched its first car, the Roadster, in 2008, Elon Musk was 37. Rimac today is just 30, with only the faintest hints of grey flecking his jet black hair. He is not keen, however, on the comparison with Musk. Tesla made 100,000 cars last year, and will hit close to triple that this year. Rimac’s vehicle output so far can be counted on two hands. “It’s an honour to be compared to him,” Rimac says, “but Tesla is much bigger. You might as well compare us to Mercedes.”

Musk, he points out, began his venture with money he made from the sale of PayPal, the online payments business. Mate Rimac (pronounced Mah-tay) began by working in his parents’ garage to turn a 1984 BMW E30 3 Series — the car is four years older than him — into a battery-powered vehicle to compete in races.

Rimac Automobili unveiled its first proper car, Concept One, at the Frankfurt Motor Show in 2011 and took orders for just eight vehicles, the last of which is currently being constructed. A second car, the C_Two — boasting a top speed of 415kph — will have a production run of 150 units, priced at $2.1m each.

The bulk of the Rimac business, however, is out of sight. Some two-thirds of its work is in supplying electrical parts, from batteries to powertrains, to the makers of performance cars. It already has an enviable customer list — its technology being found in vehicles from Aston Martin’s Valkyrie hypercar to the battery-powered Jaguar E-type Concept Zero (driven by the Duke and Duchess of Sussex after their wedding in May) and an electric hypercar from Automobili Pininfarina of Italy.

Electric technology is increasingly important to mainstream manufacturers, which are being forced to develop battery cars as a way of meeting emissions rules in regions such as Europe and China. In time, Rimac’s technology may make its way into everyday vehicles, as customers such as Porsche share the technology with mainstream sister companies such as Volkswagen or Skoda.

In the words of a Porsche spokesman, “Rimac’s ideas and approaches are extremely promising”, while the German sports car maker’s next step will be to “evaluate the transfer of technologies to [fellow VW subsidiaries] Bentley and Bugatti and of course the whole VW group”. In June, Porsche invested €18.7m in Rimac, taking a 10 per cent stake. A year ago, Rimac had raised just $10m; it has since raised $60m, and is about to close another round that will result in Mate Rimac’s stake being diluted from 55 per cent to a minority holding.

Rimac’s aim is simple: to make the best electric sports cars in the world. Yet the marque broke into the public’s consciousness last year in less positive circumstances (see below) when Richard Hammond crashed a Concept One car while filming The Grand Tour, Amazon Prime’s motoring show presented by the former BBC Top Gear team. The vehicle veered off a hill road in Switzerland, rolled and caught fire. Hammond broke a knee, but because of the density of the flammable batteries, the car burned for five days. The incident came as Rimac was hours from signing a fundraising deal to keep the business alive. It was one of many times the business has teetered on the financial brink.

Mate Rimac was born in what today is Bosnia-Herzegovina, in the poorest town in the country. His family fled to Germany during the 1990s war in the former Yugoslavia. He spent his early childhood in Frankfurt developing a love of cars by watching motoring programmes on television. When Rimac was 14, the family moved to Zagreb: he says his strong Bosnian accent made him sound “like a hillbilly”, inviting mockery from his teenage peers. “I don’t like to complain,” he says, “but it was a really, really tough time. It was really the worst.”

His talent for innovation emerged during those years, however, and he won an international invention competition with a glove that acted as a keyboard and mouse for a computer. When he turned 18 he bought the BMW — “it was totally rusty, a piece of crap” — to race. After the engine exploded in its second race, Rimac decided to transform the car into an electric performance vehicle, first with old lead acid batteries connected in sequence, then with increasingly sophisticated batteries imported from China.

He was joined by Igor Pongrac, who worked making drones for the Croatian army — the force had to make its own hardware as sanctions prevented it from buying it in. They moved into Pongrac’s father’s garage, where their late-night welding sessions drew complaints from the neighbours. A designer, Adriano Mudri, who worked at General Motors, became de facto employee number three, working evenings and nights in his spare time.

The leap from hobby to business came when a representative of the Abu Dhabi royal family, familiar with Rimac from his early fame as an inventor, asked to see their automotive work. A brochure was cobbled together. “He went to Abu Dhabi with that and called me and said they wanted two cars,” says Rimac. “I was like, ‘Great, but there is no car, there is no company’. The next day he called me and asked, ‘How much do you need?’. I had absolutely no idea.” The team drew up a plan, booked a stand at the 2011 Frankfurt Motor Show — then only 12 months away — and began working in earnest.

It can take established car companies, with legions of engineers and big budgets, the best part of a decade to design, engineer and build a car from scratch. The Rimac trio had a year. The task proved more difficult than expected: even buying commoditised parts such as door handles or headlights was beyond their means, so they had to make everything themselves. That still defines the business: Rimac remains one of the most vertically integrated car companies in the world.

Funding was scraped together from family and friends because the Abu Dhabi investors would only pay up once the cars were delivered. Sleeping on sofas or the floor, working through the night and weekends, the team had the car ready for the show. On September 13 2011, Rimac Automobili made its debut — and within days almost collapsed. At the final stages of the funding negotiation, the backers demanded the business relocate to Abu Dhabi before they would agree to inject €4.5m. Without the funding, the carmaker was in danger of folding, yet because of the potential upheaval, Rimac refused. “It was the best thing I’ve ever done,” he says.

The business remains the only carmaker in Croatia. Educated or ambitious Croatians tend to emigrate to Germany, Rimac says. “When I see all of these people here, doing this stuff, most of them would be outside Croatia if it wasn’t for this company.”

Following the Abu Dhabi setback, Rimac secured a loan of half a million euros by offering everything — the prototype car, the intellectual property and the brand — as security to a local bank. Cash has remained tight in the intervening years, with money for wages or bills rolling in sometimes with hours to spare.

Orders for the eight Concept One cars, each with a $1.2m price tag, helped keep the company afloat. Meanwhile, it designed and built electric prototypes for lesser-known vehicle makers, each job bringing in a few million euros.

By 2012 the company was in the black and stayed that way, making a €158,000 pre-tax profit on revenues of €6.1m in 2016. Last year heavy research and development spending on the C_Two pushed Rimac back into a pre-tax loss €5.8m, although revenues climbed to €20.2m.

“It was just a matter of survival, not because we wanted to be profitable but because there was no other way to survive,” says Rimac.

Chief executives or senior representatives from almost every major car manufacturer have visited the Zagreb site over the past few years, but most of the projects in Rimac’s history — around 35 in total — have never been publicly disclosed. Walking through the battery assembly room during our tour, Rimac points to black boxes on a trolley and mentions which company they have been developed for. “We are the sole supplier for it and you just saw there the composite parts being made and here is now the assembly,” he says, gesturing. “But that is not public.”

One project he can name was for Cupra, the high-performance sub-brand of Seat, the Spanish marque owned by Volkswagen. Jaime Puig, director of Cupra Racing, was impressed by the Croatian company’s approach. Rather than trying to sell existing products, he says, it asked about Cupra’s needs and offered to engineer something specific. “I was surprised that someone so young had so much experience and [had been through] so much evolution in such a short time,” Puig says, noting that the average age of Rimac employees seemed to be half that of Cupra’s. “My generation would touch everything, strip down a car, but the thing we would never touch was the battery and now we have to learn about the battery. It is a new world.”

The only well-known automotive business never to cross the threshold is Tesla. In fact, Rimac has never met Musk. “I admire him,” he says, standing by the C_Two for photos. “A lot of people wanted to introduce him to me, but I didn’t want that. I wanted to have the company on the level where I wanted it to be, and it’s still not there.”

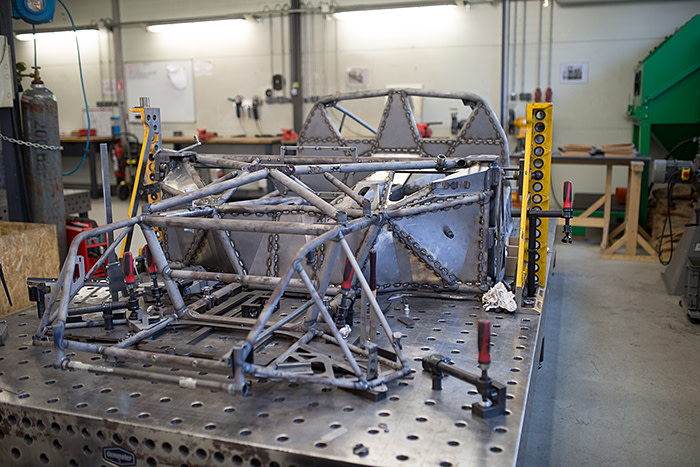

The factory feels more like a series of workshops, spread across half a dozen buildings. In the milling area, where blocks of aluminium sit behind glass with drills boring into them, Rimac picks up an ordinary looking piece of aluminium. “This is part of the Aston Martin battery,” he explains. In the next room, the frame for a Concept One is being welded by hand — it takes one-and-a-half months to make. Without chassis or wheels, it looks like a shrunken whale carcass.

As it ramps up the C_Two, the company plans to move to a new site to accommodate its swelling workforce, which has doubled to 450 in the past year. “Six months ago it was totally different; six months from now it will be totally different,” says Rimac. The new location, half an hour away, is spacious and will have crops as well as animals on site.

Rimac, a devoted vegetarian who often ends conference speeches by saying that avoiding meat is more important to tackling climate change than killing off petrol power, wants to have animals grazing at the site that will then be served up at the staff canteen. “You will see that cow going from your parking [spot] to your office and then that cow, which will have a name, will end up on your table,” he laughs. “It’s crazy idea, but I want people to think about it a little bit more.”

Despite its growth rate, the company does not plan to increase volumes beyond hundreds of cars, otherwise the larger carmakers that are its core customers would start to see it as a competitor. That still gives it room to grow, however. “What is the market for electric supercars? Honestly, no one knows. Right now it is eight Concept Ones,” says Rimac.

However, serious motorists, attuned to the guttural roar of V12 engines, are likely to be attracted by the performance of battery cars. In The Grand Tour episode, a few minutes before the fateful crash, the Concept One outpaces a Lamborghini Aventador and a Honda NSX. “I’ve never seen anything move as quickly as that,” says Jeremy Clarkson, his Lamborghini left trailing in the dust. This is because electric cars can draw huge amounts of power from their batteries for short bursts — and the technology is improving. A Tesla P100D Model S can, in short bursts, produce 500kW of power from a 100kWh battery — what is known as a C-rate of five times. Rimac’s battery for Aston Martin will achieve a C-rate of 120 times, drawing 120kW of power from just 1.3kWh. This will make the Valkyrie hybrid car, which will still have a V12 petrol engine, the fastest road-legal car in the world around a race circuit, its maker promises.

Fraser Dunn, Aston Martin’s chief engineer on the Valkyrie project, explains why the company chose Rimac technology: “If we went to a big battery provider, and asked them for a battery that met our requirements, the first answer would be no. If it was yes, it would take much longer and cost more.”

Rimac attributes much of his company’s competitiveness to its trial-and-error approach in its early days. Old photos of the business show people asleep on sofas, and stacks of batteries, bundled together with wires or cables snaking out at various angles. “This was really, really dangerous,” he says. “High voltage everywhere. It was insane.”

Rimac’s inspiration was the father of high-voltage innovations, Nikola Tesla, the pioneer of the electric AC motor, who was born within 200km of the Zagreb plant and whose name adorns the company’s boardroom. If the title had not been bagged by Musk, Rimac says his company would have been named after the inventor. Another early brand name was VST, based on v=s/t, the formula for speed.

Rimac leads the nomadic lifestyle of an automotive chief executive of a much bigger business. The previous evening, he landed from a trip at midnight, and worked on emails until 5am at home. He was in the office before 8am, and 13 hours later is showing not the faintest traces of fatigue. He is off to Germany in the morning, then to China the day after. “After 10 years, I think I got used to it,” he says. “I made this choice, you know; it’s a tough one, but you have to accept it.”

Despite the workload, Rimac’s job brings few trappings: he cannot afford one of his own cars himself, he draws a “normal” salary and is “cash poor”, although his stake in the company is worth millions.

After our meeting, he is picked up from the office by his girlfriend, who works at the company; his own car, the prized 1984 BMW, is being repaired. Despite having the status of a business rock star in Croatia, and increasingly being clasped into the same visionary bracket as Musk, Rimac remains self-effacing and humble.

As we prepare to part ways, he asks why, with an address book of global carmakers to interview, I wanted to meet him. The pilgrimage of automotive executives to his door — and the boost to the company’s order book — appear not to have inflated his ego.

Like some drivers of his supercars, it is possible that Rimac underestimates his own power.

Off the road but on the map: the crash that marked a crossroads

On a Saturday afternoon in June 2017, Mate Rimac’s phone rang. It was his team in Switzerland, where Amazon Prime’s The Grand Tour was filming with a Rimac Concept One supercar. The crew back in Zagreb had been nervous — it was, after all, a customer’s $1.2m car. They monitored the car’s performance in real time as it completed four runs up a steep, winding hill, the climax of five days of filming.

Streams of data, from speed and acceleration to a host of other metrics, flowed on to the screens. Each run up the hill had seen Richard Hammond, one of the hosts of the show, gradually drive faster as he became more comfortable with the handling of the electric supercar. First 145, then 153, 158 and finally 177kph. “The guys from Switzerland called and said everything’s done, perfect, the guys are starting to pack up the things,” recalls Rimac. “We were so happy.”

What they did not know was that Hammond had opted for a fifth and final run up the hill. A few minutes later, Rimac’s phone rang again. The words that came down the line are etched into his memory. “He said, ‘he crashed, the car is burning, he’s alive’. I was like, what? Our car burning? How is that possible?” The car had veered off the hill, crashed upside down on a road, rolled and caught fire.

Rimac said nothing to the team, but left the battery-testing room immediately. By the time he had driven home, the story had broken on Croatian media. Everyone phoned: customers, journalists and, most importantly of all, Rimac’s prospective new shareholder, Camel Group, the Chinese battery-maker.

Various factors threatened the company’s survival at this point: Camel Group might have backed out, customers might have demanded their deposits back, staff might have left, or the insurance company might have refused to pay out. “Those three weeks were hell,” says Rimac, and capped “the worst year of my life” as the company lurched from one funding crisis to another.

Rimac prepared a 29-page presentation, detailing how and why the accident happened. The speed data for the final lap was lost, but from the finish time the team estimates the car was travelling at 212kph on the final straight immediately before careering off the road. It ended up nearly 100 metres from the road, taking out a telegraph pole on the way and flying over a hillside house.

One photo angle in the file, from the crash site back up the hill, shows the house with the crest of the ridge rising above it. The angle of the slope is terrifyingly steep.

Hammond declined to comment for this article, but made a video with Rimac explaining what happened. The two are still in touch. The company has since introduced new safety features in its vehicles, including isolating the possibility of battery fires, and new driver aids to help owners harness the power.

“A lot of people told me it’s the best thing that happened to us,” says Rimac. “I would rather that it hadn’t.”

Comments