Rocket engine will need funds to reach lift off

Roula Khalaf, Editor of the FT, selects her favourite stories in this weekly newsletter.

Alan Bond is living proof that persistence pays off. The former Rolls-Royce rocket engineer has spent more than 30 years chasing his dream of space travel, fighting not just bureaucracy but also indifference to a vision many believed was impossible.

Yet the engine concept that the 72-year-old and his two partners have developed, which could eventually take an aircraft from earth to orbit and back again, is on the brink of becoming reality. Reaction Engines, the UK company formed by the three, expects next year to start building the first components for a demonstrator of their engine, named Sabre, with a view to begin testing by 2020.

The technology promises to revolutionise access to space, where launching methods have changed little since the 1960s. Elon Musk’s SpaceX venture has spent large sums searching for a faster, cheaper and reusable way to get into orbit. Though SpaceX aims to recycle the first stage of its rocket system, it still uses traditional rocket technology that requires heavy loads of liquid oxygen.

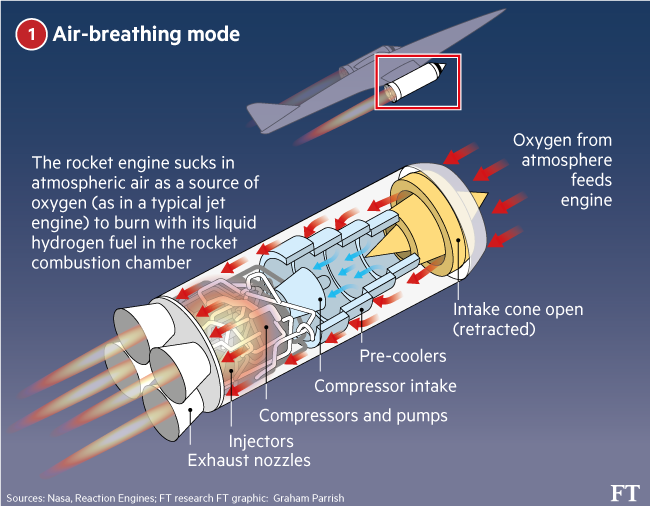

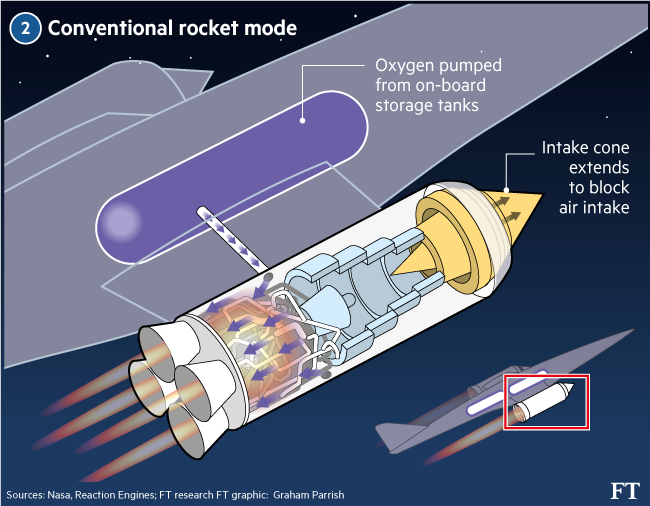

The difference is that Sabre (Synergetic Air-Breathing Rocket Engine) would take a vehicle into orbit in a reusable single-stage vehicle, or cut the cost of a two-stage launch. It would use jet engine technology that effectively “breathes” air to make 20 per cent of the journey to orbit before switching to rocket mode to complete the trip, in the process powering a vehicle to travel at up to 25 times the speed of sound in orbit. There is far less liquid oxygen to reduce speed or dampen thrust — roughly 250 tonnes less — no jettisoning of parts and the aircraft should be able to return to earth and repeat the trip.

“Single stage to orbit is the holy grail,” says Carissa Christensen, managing partner of the US-based space consultancy Tauri Group. “It is potentially transformative in terms of the economics and performance of launch into space, particularly if you combine it in a reusable format.”

Mark Thomas, Reaction Engines’ chief executive, says: “The problems [Mr Bond and his partners] fixed in the early years were unbelievably challenging, ones that other companies and countries had thrown millions of dollars at and not fixed.”

James McMicking, chief strategy officer of the UK’s Aerospace Technology Institute, estimates the engine could be “10 to 100 times more cost effective than traditional rocket technology”. Today a rocket launch, excluding the cost of a satellite, is upwards of $65m or more, according to Tauri.

Reaction’s Sabre concept has drawn interest from the US, which has for decades pursued its own version of air-breathing engine technology with Nasa’s Scramjet. However, many experts believe the UK engine is more advanced.

“Nasa is a long way from making that work in a reliable repeatable way,” says Mr McMicking. “The Scramjet will not deliver a vehicle into space. It has to be combined with rocket technology and the Scramjet does not combine technologies as Sabre does.”

The real innovation of the Reaction engine lies in its ability to cool the air passing through the jet turbine and into the rocket quickly, while expelling all moisture to prevent frosting that could block the cooling system. “The heat exchanger was the key,” says Mark Ford, head of propulsion engineering at the European Space Agency (ESA). “If that had not worked this technology would have gone nowhere.”

It was this innovation, which takes the temperature of the air inside the engine from 1,000C to minus 150C in less than 1/20th of a second, creating the compressed oxygen needed for the rocket stage, that brought ESA onboard in 2008. Subsequently the technology has been validated by the US Air Force Research Laboratory as being viable.

The UK government, through ESA, has allocated £60m to fund the demonstrator phase, while BAE Systems, the UK defence company, contributed £20m last year in exchange for a 20 per cent stake. But more money will be needed. Mr Ford estimates the total cost of eventually putting Sabre on to the wing of a vehicle at £500m-£1bn.

“We will need investment,” says Mr Thomas. “This programme will get larger and the funds required will be exponentially larger.” He hopes the technology will interest partners from outside the space sector. Its cooling concept has applications well beyond aerospace, stretching to transport, power systems and aviation. “It can be used anywhere you have thermal management challenges, where you need to transfer heat efficiently,” he says.

But significant challenges remain to prove the technology works as promised, not least in developing an aircraft to be powered by the Sabre system, which could require billions of dollars. “The vehicle is just a concept at the moment,” says Mr Ford. “It is lagging behind the engine in terms of development.” There are also challenges in making components that can be reused and maintained cost effectively.

Much of the work being carried out by Reaction on components, materials and precision manufacturing, for example, will be useful in ways that cannot yet be imagined, says Professor Iain Gray, head of aerospace at Cranfield University. “This is not a conventional project. It is not a natural evolution in civil aerospace. It is a game-changer project.”

The key will be to ensure the UK maintains sufficient support to ensure the project is not overtaken. The US, China and Russia are all working on hypersonic concepts.

“If the UK takes too long to develop this, the cat is out of the bag,” says Mr Ford. “Like all technologies, it does not take long for second and third adopters to come along.” But success is not a given he says. “It is still a very high-risk programme. There is no guarantee.”

Comments